Blog

Reach Out My Experience

Added 15th March 2018

#ROMyE - Amy Bracey, Senior Surveyor, Colliers International

‘I was introduced to ‘My Future My Choice’ via Bristol Junior

Chambers and was initially interested at being able to improve my

mentoring skills whilst also being able to ‘give something back’. The

experience has been invaluable,

and I have gained so much more than simply improving my mentoring

skills. I learnt how to provide guidance and assistance even outside of

my professional experience and found the programme very rewarding. The

students were inspirational, and it was refreshing

to hear aspirations and hopes for the future that weren’t tainted as

ours so often our by reality, and that is something that I’ve taken away

myself. The only limitations are those we set up in our minds – and

it’s helpful to be reminded of that every now

and then! I have to say since the programme has stopped I’ve really

missed the interaction with the students – they even kept me up to date

with what’s ‘cool’ – sometimes inadvertently reminding me that I’m

slightly past it!’

#ROMyE - Amber Waters, Graduate Engineer, Rolls-Royce

#ROMyE - Mike Joy and Christine Osborne host the Plan My Future programme

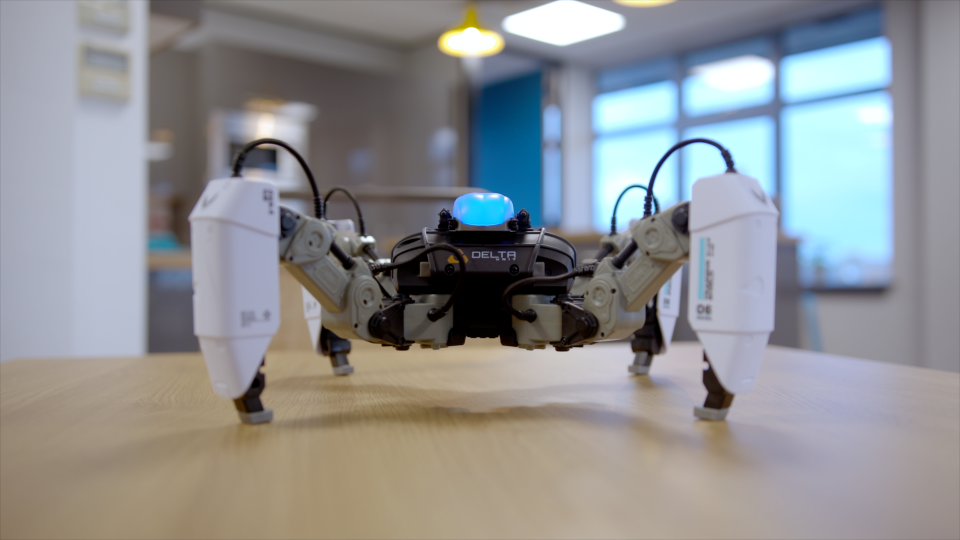

#ROMyE - John Rees, Reach Robotics

John is a founder of Reach Robotics, he volunteered for a day with 14 year olds at Bristol Technology & Engineering Academy helping a small team of students design and builld radio controlled aeroplanes. A great experience for him and the students. Mindful that he could do more and that his time for volunteering is limited, running a fast expanding business, he invited us in to see what happens at Reach Robotics.

Folowing the meet up, Reach Robotics are offering quick tours for small groups of students to an their exciting work place where mechanical toys and augmented reality become big business.

Reach have donated two Mekamon Robots for demo applications in our Cranes and hydraulics workshops and booked in My Future My Choice for a staff away day to explore some low-tech ways of playing and learning that will help develop our resources. John and maybe some of his 35 string team will also get involved in our cosultations to help helping us design new cards for our Jobs Top Trump Game - which needs more examples of emerging and possibly as yet unknown job roles like the jobs at Reach Robotics.

#ROMyE, Phil Rowles, Engineer

Phil joined in with a project funded by the Royal Academy of Engineering at the Bristol Museum. Training sessions with scientists and engineers pooled ideas for delivery of public and schools STEM workshops in 2011. Phil went away and applied his practical skills, scientific knowledge and experience as a mechanical engineer designing hydraulic systems for helicopters to create resources for interactive learning.

A series of demonstrations using syringes and tubing showed how pressures could be used to actuate machines and generate power. Teachers reported that children not known fro their mathematical ability where understanding and explaining ratios and fractions after handling the devices.

Phil kindly donated the resources and his ideas for use in future workshops . He acted as consultant to the next phase of the development of Cranes and Hydraulic resources that has seen a much wider use of his input. (See #ROMyE Glyn Griffith below)

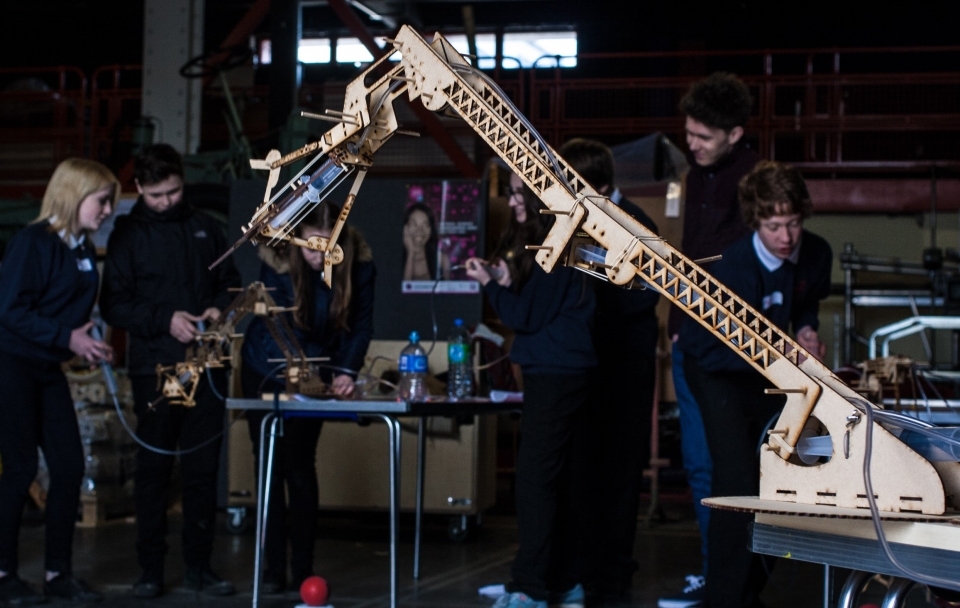

#ROMyE, Glyn Griffith, University of Bath PhD Student

The Museum of Bath at Work hosted a group of engineers and challenged them with the task of turning Phil Rowles' (see above) ideas for learning about mechanical advantage into resource that could be replicated to engage much larger groups. Glyn went away from this workshop fired up to complete and finish the development of a viable product. He has since got a job where he must see unique inventive ideas through to production and he claims that talking about the development of this learning resource at interview was part of the reason he got his job.

Glyn produced prototypes in MDF using technology at his university and Glyn and MFMC ran a series of workshops with schools, engaging other engineers and crane companies in the workshop. These workshops were a huge success and the availability of the mass produced parts gives clear evidence that he has made a powerful tool for learning.

The draw back was the cost and the use of MDF which although safe to handle was not as environmentally friendly as we would like. Glyn was by now being paid for delivery of school workshops and he took on the challenge of redesigning the resources so they could be punched out of cardboard. This resource has since been used with thousands of young people of all ages and new workshop ideas have been created off the back of the design that throw unique lifting and access challenges at older students

Support from businesses like Liebherr, European leaders in crane design and manufacturing have been crucial and Edward Hudson from Lieberr has seen the value in using this resource to challenge the annual intake of Liebherr Mechanical Engineering Apprentices to work with teams of school students to reach out their experience to a younger generation of potential engineers.

Blog Tags

- 'My Future Clubs' (3)

- Aviation (35)

- Bristol Loves Tides (21)

- Build My Future (20)

- Carboard Boat Race (1)

- Cards (8)

- careers (2)

- catch the train to my future (2)

- Citizenship (21)

- Classroom Afloat (9)

- Coaching (2)

- community (16)

- competition (16)

- Constructing and creating (98)

- consultancy (1)

- CPD (14)

- Crossing Coasts - Windrush Project (3)

- Design My School (1)

- Design solutions (12)

- DIY Energy (4)

- Documentary film making (1)

- Early Years (3)

- Engineering (100)

- Engineers (25)

- Engineers Top Trumps Pack (8)

- Entrepenuer (1)

- Exhbitions on Balmoral (2)

- Family (26)

- female engineers (29)

- Festivals (1)

- Financial Education (1)

- Goal Setting (4)

- Higher Education (9)

- Home Learning (2)

- IMechE (4)

- Ingenious (8)

- Institute of Structural Engineers (1)

- Learning Ships (31)

- Learning Ships (3)

- learning Ships (1)

- Lifting Aspirations - Accessing Engineering (20)

- Literacy (1)

- Museum (15)

- outdoors learning (14)

- parents (5)

- PHSE (17)

- Plan My Future (1)

- Power and thrust (12)

- Primary (24)

- Primary (12)

- Primary School (35)

- Reach Out My Experience (2)

- Resources (11)

- Resources - Card Game, Posters, Workbooks etc (7)

- Rocking the Boat (1)

- Science Festival (5)

- Science learning (18)

- Secondary (26)

- Secondary school (52)

- Self Belief (10)

- self evaluation (7)

- Shipping 2050 (2)

- survey (1)

- Sustainability (1)

- transition (13)

- UTC (2)

- Visioning (26)

- Volunteering (35)

- Windrush (2)

- Work Experience (23)

- Workshops (32)

- Wroughting (1)

- 'My Future Clubs' (3)

- Aviation (35)

- Bristol Loves Tides (21)

- Build My Future (20)

- Carboard Boat Race (1)

- Cards (8)

- careers (2)

- catch the train to my future (2)

- Citizenship (21)

- Classroom Afloat (9)

- Coaching (2)

- community (16)

- competition (16)

- Constructing and creating (98)

- consultancy (1)

- CPD (14)

- Crossing Coasts - Windrush Project (3)

- Design My School (1)

- Design solutions (12)

- DIY Energy (4)

- Documentary film making (1)

- Early Years (3)

- Engineering (100)

- Engineers (25)

- Engineers Top Trumps Pack (8)

- Entrepenuer (1)

- Exhbitions on Balmoral (2)

- Family (26)

- female engineers (29)

- Festivals (1)

- Financial Education (1)

- Goal Setting (4)

- Higher Education (9)

- Home Learning (2)

- IMechE (4)

- Ingenious (8)

- Institute of Structural Engineers (1)

- Learning Ships (31)

- Learning Ships (3)

- learning Ships (1)

- Lifting Aspirations - Accessing Engineering (20)

- Literacy (1)

- Museum (15)

- outdoors learning (14)

- parents (5)

- PHSE (17)

- Plan My Future (1)

- Power and thrust (12)

- Primary (24)

- Primary (12)

- Primary School (35)

- Reach Out My Experience (2)

- Resources (11)

- Resources - Card Game, Posters, Workbooks etc (7)

- Rocking the Boat (1)

- Science Festival (5)

- Science learning (18)

- Secondary (26)

- Secondary school (52)

- Self Belief (10)

- self evaluation (7)

- Shipping 2050 (2)

- survey (1)

- Sustainability (1)

- transition (13)

- UTC (2)

- Visioning (26)

- Volunteering (35)

- Windrush (2)

- Work Experience (23)

- Workshops (32)

- Wroughting (1)

Blog Archives

- September 2025 (2)

- August 2025 (1)

- July 2025 (4)

- April 2025 (3)

- November 2024 (3)

- October 2024 (3)

- September 2024 (3)

- August 2024 (2)

- July 2024 (2)

- May 2024 (2)

- January 2024 (1)

- December 2023 (4)

- October 2023 (2)

- August 2023 (2)

- July 2023 (2)

- June 2023 (1)

- May 2023 (1)

- April 2023 (1)

- March 2023 (2)

- February 2023 (1)

- January 2023 (1)

- November 2022 (1)

- September 2022 (2)

- August 2022 (1)

- July 2022 (4)

- April 2022 (1)

- March 2022 (1)

- December 2021 (1)

- October 2021 (2)

- September 2021 (5)

- July 2021 (2)

- June 2021 (1)

- May 2021 (3)

- April 2021 (1)

- March 2021 (2)

- February 2021 (2)

- December 2020 (2)

- November 2020 (1)

- October 2020 (5)

- August 2020 (1)

- July 2020 (1)

- June 2020 (1)

- May 2020 (2)

- April 2020 (2)

- January 2020 (1)

- December 2019 (2)

- November 2019 (2)

- September 2019 (2)

- August 2019 (2)

- July 2019 (3)

- June 2019 (5)

- May 2019 (4)

- April 2019 (2)

- March 2019 (1)

- December 2018 (1)

- November 2018 (2)

- October 2018 (7)

- September 2018 (2)

- August 2018 (1)

- July 2018 (5)

- June 2018 (2)

- May 2018 (3)

- April 2018 (1)

- March 2018 (5)

- February 2018 (3)

- November 2017 (2)

- October 2017 (1)

- August 2017 (1)

- July 2017 (6)

- May 2017 (2)

- April 2017 (2)

- March 2017 (2)

- February 2017 (1)

- January 2017 (2)

- December 2016 (3)

- November 2016 (6)

- August 2016 (3)

- July 2016 (4)

- June 2016 (1)

- May 2016 (1)

- March 2016 (3)

- February 2016 (1)

- December 2015 (2)

- November 2015 (3)

- October 2015 (1)

- September 2015 (1)

- August 2015 (1)

- July 2015 (5)

- May 2015 (3)

- April 2015 (2)

- March 2015 (3)

- February 2015 (1)

- January 2015 (2)

- December 2014 (2)

- November 2014 (6)

- October 2014 (1)

- September 2014 (3)

- August 2014 (1)

- July 2014 (3)

- June 2014 (1)

- May 2014 (2)

- April 2014 (1)

- March 2014 (3)

- February 2014 (2)

- January 2014 (3)

- December 2013 (6)

- November 2013 (4)

- October 2013 (3)

- September 2013 (1)

- August 2013 (4)

- July 2013 (4)

- June 2013 (2)

- May 2013 (1)

- April 2013 (1)

- March 2013 (2)

- January 2013 (1)

- December 2012 (2)

- October 2012 (3)

- September 2012 (2)

- August 2012 (1)

- July 2012 (6)

- May 2012 (3)

- April 2012 (2)

- March 2012 (1)

- February 2012 (4)

- January 2012 (4)

- November 2011 (2)

- October 2011 (2)

- September 2011 (7)

- August 2011 (2)

- November -0001 (1)